Printed Circuits Handbook by Clyde F. Coombs Jr

Tài liệu về mạch in gồm các chương nội dung sau :

Chapter 1. Legislation and Impact on Printed Circuits

Chapter 2. ELECTRONIC PACKAGING AND HIGH-DENSITY INTERCONNECTIVITY

Chapter 3. Semiconductor Packaging Technology

Chapter 4. Advanced Component Packaging

Chapter 5. Types of Printed Wiring Boards

Chapter 6. Introduction to Base Materials

Chapter 7. Base Material Components

Chapter 8. Properties of Base Materials

Chapter 9. Base Materials Performance Issues

Chapter 10. The Impact of Lead-Free Assembly on Base Materials

Chapter 11. Selecting Base Materials for Lead-Free Assembly Applications

Chapter 12. Laminate Qualification and Testing

Chapter 13. Physical Characteristics of the PCB

Chapter 14. The PCB Design Process

Chapter 15. Electrical and Mechanical Design Parameters

Chapter 16. Current Carrying Capacity in Printed Circuits

Chapter 17. PCB Design for Thermal Performance

Chapter 18. Information Formating and Exchange

Chapter 19. Planning for Design, Fabrication, and Assembly

Chapter 20. Manufacturing Information, Documentation,and Transfer Including CAM Tooling for Fab and Assembly

Chapter 21. Embedded Components

Chapter 22. Introduction to High-Density Interconnection (HDI) Technology

Chapter 23. Advanced High-Density Interconnection (HDI) Technologies

Chapter 24. Drilling Processes

Chapter 25. Precision Interconnect Drilling

Chapter 26. Imaging

Chapter 27. Multilayer Materials and Processing

Chapter 28. Preparing Boards for Plating

Chapter 29. Electroplating

Chapter 30. Direct Plating

Chapter 31. PWB Manufacture Using Fully Electroless Copper

Chapter 32. Printed Circuit Board Surface Finishes

Chapter 33. Solder Mask

Chapter 34. Etching Process and Technologies

Chapter 35. Machining and Routing

Chapter 36. Bare Board Test Objectives and Definitions

Chapter 37. Bare Board Test Methods

Chapter 38. Bare Board Test Equipment

Chapter 39. HDI Bare Board Special Testing Methods

Chapter 40. Assembly Processes

Chapter 41. Conformal Coating

Chapter 42. Solderability: Incoming Inspection and Wet Balance Technique

Chapter 43. Fluxes and Cleaning

Chapter 44. Soldering Fundamentals

Chapter 45. Soldering Materials and Metallurgy

Chapter 46. Solder Fluxes

Chapter 47. Soldering Techniques

Chapter 48. Soldering Repair and Rework

Chapter 49. Press-Fit Interconnection

Chapter 50. Land Grid Array Interconnect

Chapter 51. Acceptability and Quality of Fabricated Boards

Chapter 52. Acceptability of Printed Circuit Board Assemblies

Chapter 53. Assembly Inspection

Chapter 54. Design for Testing

Chapter 55. Loaded Board Testing

Chapter 56. Conductive Anodic Filament Formation

Chapter 57. Reliability of Printed Circuit Assemblies

Chapter 58. Component-to-PWB Reliability: The Impact of Design Variables and Lead Free

Chapter 59. Component-to-PWB Reliability: Estimating Solder-Joint Reliability and the Impact of Lead-Free Solders

Chapter 60. Process Waste Minimization and Treatment

Chapter 61. Flexible Circuit Applications and Materials

Chapter 62. Design of Flexible Circuits

Chapter 63. Manufacturing of Flexible Circuits

Chapter 64. Termination of Flexible Circuits

Chapter 65. Multilayer Flex and Rigid/Flex

Chapter 66. Special Constructions of Flexible Circuits

Chapter 67. Quality Assurance of Flexible Circuits

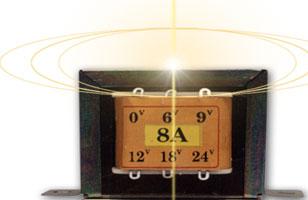

Tính toán quấn máy biến áp 1 pha tần số 50Hz

Tính toán quấn máy biến áp 1 pha tần số 50Hz  Cấu tạo, nguyên tắc hoạt động của Transitor

Cấu tạo, nguyên tắc hoạt động của Transitor  Nguyên lý và sử dụng nguồn xung hay bộ biến đổi nguồn DC-DC

Nguyên lý và sử dụng nguồn xung hay bộ biến đổi nguồn DC-DC  Làm LED trái tim với 8501

Làm LED trái tim với 8501  Ký hiệu, Hình dạng, kiểm tra, Xác định chân Transitor

Ký hiệu, Hình dạng, kiểm tra, Xác định chân Transitor